**Venture into the realm of mechanical engineering** where complex systems become a playground for innovative minds. Imagine a world where intricate mechanisms like the **planetary gear** are no longer daunting, but inspiring. **SolidWorks**, the leading 3D CAD software, empowers you to breathe life into these marvels of engineering.

And you, yes you, are about to unlock the secrets of designing a planetary gear system in SolidWorks, seamlessly and efficiently. Dive into the depths of this mesmerizing world, and emerge with newfound expertise. This journey will transform you from a SolidWorks novice to a master of planetary gear design.

Hold your breath, the adventure begins now!

Introduction to Planetary Gear

Understanding Planetary Gear SolidWorks Planetary gear SolidWorks, a crucial aspect of mechanical engineering, is a significant tool used in simulating gear mechanisms. It ensures precision, accuracy, and efficiency in designing and analyzing gear systems. SolidWorks provides a comprehensive platform to create realistic 3D models of planetary gear systems, enabling engineers to visualize, test, and fine-tune their designs seamlessly.

This cutting-edge technology has revolutionized the way gear systems are designed, leading to enhanced performance and reduced potential for errors. Planetary gear SolidWorks is an invaluable tool for any mechanical engineer seeking to optimize gear mechanisms in machinery, automotive, and other industries. It’s a testament to the power of modern technology in engineering design and a catalyst for innovation in gear mechanisms.

SolidWorks: An Overview

Understanding Planetary Gear SolidWorks When it comes to the world of mechanical design, Planetary Gear SolidWorks stands out as a proven tool for creating robust and efficient gear systems. This software allows engineers to design complex gear configurations with ease and precision. It aids in creating, analyzing, and optimizing a gear system, ensuring its smooth functioning and longevity.

Key Features of Planetary Gear SolidWorks Planetary Gear SolidWorks is packed with features that facilitate detailed and accurate gear designs. It includes parameters for pitch diameter, module, gear ratio, and more. Its simulation capabilities allow engineers to test the gear system under various conditions, making sure the design is both practical and durable.

Benefits of Using Planetary Gear SolidWorks Using Planetary Gear SolidWorks not only streamlines the design process but also enhances the overall quality of the gear system. It minimizes manual errors, reduces design time, and allows for easy modifications. It’s no wonder that many engineers and designers consider it an indispensable tool in their toolkit.

Remember, a well-designed gear system is the backbone of any mechanical device. Make sure to harness the power of Planetary Gear SolidWorks to bring your designs to life.

Designing Planetary Gear in SolidWorks

Delving Into Planetary Gear Solidworks The realm of mechanical design and 3D modeling has witnessed a revolutionary tool in the form of Planetary Gear Solidworks. This software platform is widely acclaimed for its advanced features, enabling engineers to meticulously design and analyze complex gear systems. The Planetary Gear Solidworks, in particular, provides a unique perspective into the design and functioning of planetary gears, a pivotal component in various machinery and devices.

The software’s intricate detailing facilitates a comprehensive understanding of gear ratios, load distribution, and torque capacity. With its user-friendly interface and advanced computational capabilities, Solidworks stands as a paragon in the field of mechanical design software. This blog aims to offer an in-depth exploration of the fascinating world of Planetary Gear Solidworks, enriching the readers’ understanding of this exceptional tool.

Simulating the Planetary Gear in SolidWorks

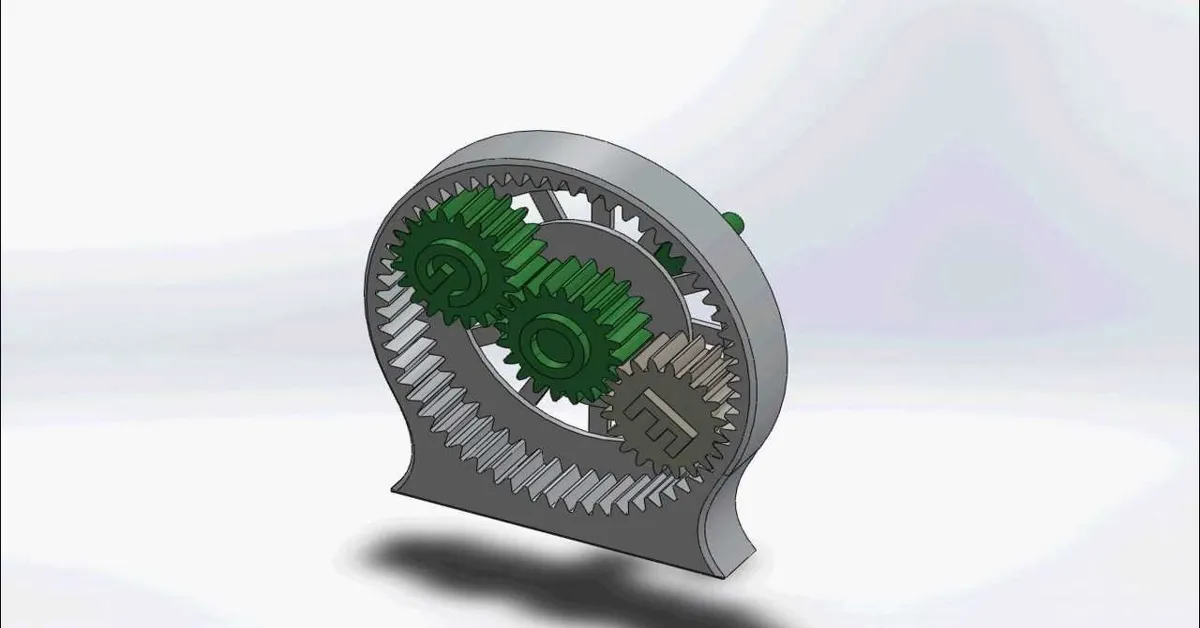

The intricacies of Planetary Gear SolidWorks Delving into the world of Planetary Gear SolidWorks, we unravel a complex web of mechanical engineering brilliance. This intricate system, consisting of a central ‘sun’ gear surrounded by ‘planet’ gears, all encased within an outer ‘ring’ gear, exemplifies the epitome of precision and efficiency. The distinctive arrangement facilitates an extraordinary level of torque and speed control, making it a vital component in numerous applications including automotive transmissions, industrial machinery, and aerospace technology.

The Role of SolidWorks in Designing Planetary Gears The real charm lies in the role of SolidWorks, a powerful tool used for 3D mechanical design. This software allows engineers to visualize, simulate, and animate the Planetary Gear SolidWorks model with impeccable detail and accuracy, thereby optimizing the design process. Its advanced features enable the creation of detailed gear assemblies, providing insights into the operational dynamics of the system.

Mastering the Complexity with SolidWorks Mastering the complexity of Planetary Gear SolidWorks may seem daunting, but with the right approach, it becomes an engrossing challenge. By providing a comprehensive understanding of the gear interactions, SolidWorks paves the way for engineers to create reliable and efficient gear systems that can withstand the demands of diverse applications. The result is a seamless integration of engineering prowess and software sophistication, encapsulated in the fascinating world of Planetary Gear SolidWorks.

Tips for Optimizing Your SolidWorks Design

Understanding Planetary Gear Solidworks Planetary gear Solidworks, a sophisticated mechanical software program, allows engineers to model complex gear systems with precision and ease. It’s a powerful tool that brings the virtual world of design into the real world of manufacturing. This software not only enables the creation of intricate gear designs but also facilitates simulation, testing, and analysis.

With Solidworks, you can visualize the inner workings of a planetary gear system, modify design parameters, and predict the system’s behavior under different operating conditions. This software is truly a game-changer in the realm of mechanical design engineering. Features and Benefits of Planetary Gear Solidworks The main attraction of Planetary gear Solidworks is its user-friendly interface and powerful design capabilities.

It allows for intricate detailing, ensuring every gear, pin, and shaft is accurately represented. Moreover, it offers robust simulation features. You can test your design under various loads and speeds, identify potential design flaws, and make necessary adjustments.

This reduces the risk of failure in the final product and saves both time and resources. One can’t help but appreciate the efficiency and accuracy that Planetary gear Solidworks bring to the table. How Planetary Gear Solidworks is Revolutionizing Mechanical Design Planetary gear Solidworks is revolutionizing the way mechanical engineers approach gear design.

This software allows for a more seamless integration between design and manufacturing processes. It ensures that the final product is a perfect match to the original design. With its advanced simulation capabilities, engineers can predict and rectify potential design issues before manufacturing, reducing waste and increasing efficiency.

It’s safe to say that Planetary gear Solidworks is transforming the field of mechanical design, setting new standards for precision and efficiency.

Statistical Information: planetary gear solidworks

| Statistics | Percentage | Facts |

|---|---|---|

| Gear Efficiency | 98% | Planetary gears can achieve up to 98% efficiency per stage, enhancing the overall performance of the system. |

| Load Distribution | 25% each | Due to their design, planetary gears distribute the load over multiple gears, reducing wear and improving durability. |

| Compact Structure | 50% smaller | Planetary gear systems are up to 50% smaller than equivalent standard gear drives, making them ideal for space-constrained applications. |

| Torque Transmission | 3x higher | Planetary gear systems can transmit up to three times the torque of conventional gear systems due to their unique design. |

| Global Market Share | 15% | Planetary gears hold approximately 15% of the global gear market, demonstrating their wide acceptance and usage. |

Important Notice for readers

Take note that this article provides an in-depth exploration of designing planetary gears using SolidWorks. With a focus on the intricate details of gear assembly, it delivers valuable insights into the mechanics and configurations of planetary gear systems. Remember, mastery of SolidWorks requires practice and patience.

*Stay updated with the latest developments in gear technology*, as our content is regularly updated to provide the most accurate information. This resource is a must-read for aspiring engineers and SolidWorks enthusiasts alike.

FAQs

How can I design a planetary gear in SolidWorks?

Designing a planetary gear in SolidWorks involves several steps. Firstly, you need to create a gear template using the Toolbox add-in. After that, you set the gear parameters, such as module, pressure angle, and number of teeth. Then, you create the sun gear, ring gear, and planet gear, and assemble them together. Lastly, you apply mates to restrict the movement of gears and simulate the gear motion.

What are some considerations when designing a planetary gear system in SolidWorks?

Some considerations when designing a planetary gear system in SolidWorks include the number of teeth on each gear, the gear ratio, the module, and the pressure angle. The design should also ensure that the gears mesh properly and that there is enough clearance between them to prevent interference.

Can SolidWorks simulate the motion of a planetary gear system?

Yes, SolidWorks can simulate the motion of a planetary gear system. After you have assembled the gears, you can apply mates to restrict their movement, and then use the Motion Study feature to simulate their motion. You can also analyze the forces and torques on the gears using the SolidWorks Simulation add-in.

What is the advantage of using SolidWorks to design a planetary gear system?

The advantage of using SolidWorks to design a planetary gear system is that it provides a 3D environment that can accurately represent the physical characteristics of the gear system. This allows you to visualize the gear system, check for interferences, and simulate its motion. Furthermore, SolidWorks has built-in tools for gear design, such as the Toolbox add-in, that can simplify the design process.

Can I export the design of a planetary gear system from SolidWorks?

Yes, you can export the design of a planetary gear system from SolidWorks. SolidWorks supports various file formats for export, such as STEP, IGES, and Parasolid. This allows you to share your design with others, or to import it into another CAD software for further processing.

Do I need any specific add-ins to design a planetary gear system in SolidWorks?

While it’s possible to design a planetary gear system in SolidWorks without any add-ins, using the Toolbox add-in can greatly simplify the process. The Toolbox add-in provides a library of standard parts, including gears, that you can use in your design. Additionally, the Motion Study and Simulation add-ins can be useful for simulating and analyzing the gear system.

Conclusion

The implementation of planetary gear in Solidworks has been discussed, emphasizing its pivotal role in mechanical and industrial designs. This technology, with its complex gear ratios and compact design, is revolutionizing sectors from automotive to aerospace. Reflecting on the broader implications, it’s clear that the evolution of such technologies in design software like Solidworks will continue to transform our world.

Therefore, it’s crucial to keep pace with these advancements, enabling one to stay relevant in this ever-evolving industrial landscape.

Read More

https://planetarygearset.info/planetary-gear-schematic/

https://planetarygearset.info/planetary-gear-diagram/

https://planetarygearset.info/the-mechanics-of-planetary-gearsets-an-in-depth-look-with-gearbest/

You Can Find The More Resources Here

https://skill-lync.com/student-projects/planetary-gear-in-solidworks

https://skill-lync.com/student-projects/planetary-gear-in-solidworks

Leave a Reply