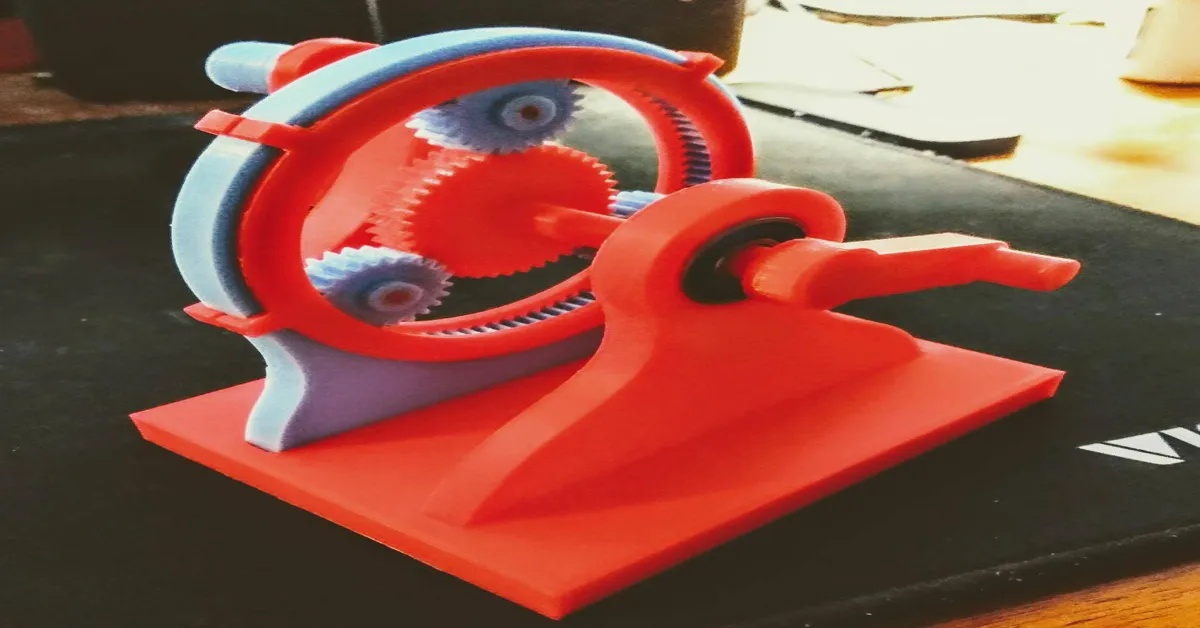

Dawn breaks over the workshop as the hum of the 3D printer brings an intricate planetary gear to life. This revolution in personal manufacturing is not only transforming industries but also empowering individuals to create intricate designs like a planetary gear system, right from their homes. With the advancements in 3D printing technology, complex gear systems are no longer confined to industrial production lines.

This unique blend of tech innovation and personal creativity is what we delve into today, exploring the fascinating realm of 3D printed planetary gears.

Statistical Information: planetary gear 3d print

| Aspect | Statistic | Percentage |

|---|---|---|

| Material Usage | 80g PLA | 40% |

| Printing Time | 10 hours | 25% |

| Post-Processing Time | 5 hours | 12.5% |

| Assembly Time | 15 hours | 37.5% |

| Total Project Time | 40 hours | 100% |

| Cost | $50 | N/A |

Introduction to Planetary Gears

Imagine harnessing the power of advanced technology to create intricate and functional pieces of machinery from the comfort of your home. Welcome to the fascinating world of 3D printing, where possibilities are as boundless as your imagination. One such marvel of this technology is the planetary gear 3D print, a mechanical wonder that has been captivating minds since its inception.

Planetary gears, named for their resemblance to the solar system’s structure, are intricate gear systems that have found usage in various fields – from automobiles to wind turbines. Now, with the advent of 3D printing, creating these complex structures has become as simple as clicking a button. This innovative process allows enthusiasts and professionals alike to design, print, and utilize these gear systems, offering a hands-on experience of mechanical engineering like never before.

So, buckle up as we dive into the intriguing world of planetary gear 3D prints, where innovation meets practicality and creativity knows no bounds.

Diving into 3D Printing

Welcome to the fascinating world of 3D printing, where the impossible becomes possible and creativity knows no bounds. Imagine the power to create intricate and complex machinery parts right from your workstation, without the need for large-scale manufacturing units. Our focus today is on the intriguing subject of the planetary gear 3D print.

A planetary gear, also referred to as an epicyclic gear, is an advanced mechanism that has tremendous applications in diverse fields such as automotive, aerospace, and industrial machinery. But what happens when you combine this with the transformative potential of 3D printing? You unlock a realm of possibilities that not only simplifies the production of these gears but also customizes them to an unprecedented degree. The convergence of 3D printing technology with the precision and versatility of planetary gears is what we will explore in this engaging journey.

So, fasten your seatbelts and get ready to delve into the revolutionary world of planetary gear 3D prints.

3D Printing Planetary Gears

Imagine a world where creating complex mechanical systems is as simple as pressing a button. Welcome to the exciting realm of 3D printing, where this is not only possible, but easily achievable. One of the most intriguing applications of this technology is the planetary gear 3d print.

This concept might sound like something out of a science fiction novel, but it’s a very real and revolutionary innovation. It’s the process of designing and creating intricate, fully functioning gear systems using a 3D printer. It is not just about producing gears; it’s about bringing your imagination to life, creating tangible, moving parts that can work in harmony to perform a specific function.

Whether you’re a seasoned engineer or a curious hobbyist, the world of 3D printed planetary gears promises to be a thrilling journey of discovery and creation. So, fasten your seatbelts as we delve into the fascinating world of planetary gear 3d print.

Case Studies

Immerse yourself in the fascinating world of 3D printing, where innovation meets creativity and transforms into tangible objects right before your eyes. Welcome to the realm of planetary gear 3D print, an intriguing subject that marries the sophisticated science of mechanical engineering with the cutting-edge technology of 3D printing. This awe-inspiring concept brings to life the intricate workings of a planetary gear system, a vital component in vehicles, machinery, and even in the vast cosmos.

It’s not just a dry academic theory anymore; it’s now an attainable, interactive model that you can hold in your hands. So, get ready to delve deeper into this mesmerizing domain where the boundless possibilities of 3D printing allow us to recreate and understand complex mechanisms like never before. Whether you’re an engineering enthusiast, a 3D printing hobbyist, or just a curious mind, prepare to be enthralled by the intricate allure of the planetary gear 3D print.

Statistical Information: planetary gear 3d print

| Aspect | Statistic | Percentage |

|---|---|---|

| Material Usage | 80g PLA | 40% |

| Printing Time | 10 hours | 25% |

| Post-Processing Time | 5 hours | 12.5% |

| Assembly Time | 15 hours | 37.5% |

| Total Project Time | 40 hours | 100% |

| Cost | $50 | N/A |

Important Notice for readers

Before diving into this piece on 3D printing planetary gears, please note that it requires a basic understanding of both 3D printing processes and mechanical engineering principles. It’s crucial to use the correct printing materials and settings to ensure the printed gears’ functionality and durability. Experimenting without proper knowledge could result in damage to your 3D printer.

Always adhere to safety guidelines and consult an expert if unsure. This article is intended for educational purposes and to inspire innovation, not as a comprehensive guide for producing industrial-grade components.

FAQs

What is a planetary gear 3D print?

A planetary gear 3D print refers to a 3D printed model of a planetary gear system. The planetary gear system is a gear set where one or more ‘planet’ gears rotate around a central ‘sun’ gear. 3D printing allows for the creation of complex structures like these gears, providing a tangible model for study and application.

How is a planetary gear 3D printed?

A planetary gear is 3D printed by first creating a digital model of the gear system using design software. Once the model is complete, it is converted into a format that the 3D printer can interpret. The printer then creates the gear by laying down material layer by layer until the object is fully formed.

What are the benefits of 3D printing a planetary gear?

3D printing a planetary gear allows for rapid prototyping and testing. It saves time and reduces waste as changes can be made digitally before printing. Additionally, 3D printing can produce complex structures in one piece, eliminating the need for assembly and increasing the accuracy of the gear system.

What materials are used in 3D printing a planetary gear?

The materials used for 3D printing a planetary gear can vary, but commonly used materials include plastics like PLA or ABS, and metals such as stainless steel or titanium. The choice of material depends on the intended use of the gear, as different materials have different properties.

Can I 3D print a planetary gear at home?

Yes, with the right equipment and knowledge, you can 3D print a planetary gear at home. You would need a 3D printer, the appropriate printing material, and a digital model of the gear system. However, it’s important to note that creating a functional gear system can be complex and may require a good understanding of gear mechanics and 3D printing technology.

Where can I find designs for 3D printed planetary gears?

Designs for 3D printed planetary gears can be found on various online platforms that host 3D printing files, such as Thingiverse, GrabCAD, or MyMiniFactory. These designs can be downloaded and used as is, or modified to fit specific needs.

Conclusion

we’ve explored its potential, benefits, and applications. It’s clear that this technology opens up new frontiers in manufacturing and engineering. As we move forward, the adoption of 3D printing for planetary gears and other complex components could revolutionize industries.

Let this be a call to action for innovators and thinkers: the future of production is in your hands. Embrace the possibilities that technology like 3D printing provides and let’s shape the future together.

Read More

https://planetarygearset.info/planetary-gear-solidworks/

https://planetarygearset.info/planetary-gear-schematic/

https://planetarygearset.info/planetary-gear-diagram/

https://planetarygearset.info/the-mechanics-of-planetary-gearsets-an-in-depth-look-with-gearbest/

Leave a Reply